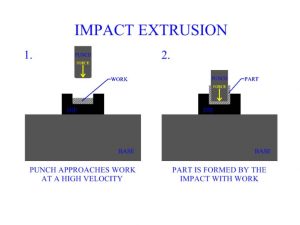

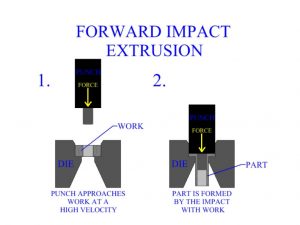

Impact extrusion is a specialized forming technique that differs from conventional extrusion by utilizing cold metal billets instead of heated materials. In this process, a metal slug is subjected to extremely high pressure in a single, rapid stroke, forcing it into the desired shape with remarkable efficiency. This method allows for the creation of complex components with excellent dimensional accuracy and surface finish, all while maintaining cost-effectiveness and high quality.

One of the key advantages of impact extrusion is its speed. As a single-stroke process, it enables rapid production cycles, significantly reducing lead times and increasing throughput. The process is highly repeatable, delivering precision parts that consistently meet stringent quality standards.

While the impact extrusion process itself is straightforward, the design and manufacture of the required tooling demand significant expertise. Our extensive experience in tooling development ensures our customers benefit from parts with tight tolerances, superior strength, and industry-leading fabrication quality.

For more details, please refer to http://thelibraryofmanufacturing.com/impact_extrusion.html

source: thelibraryofmanufacturing.com