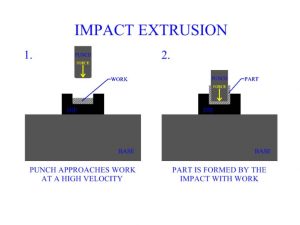

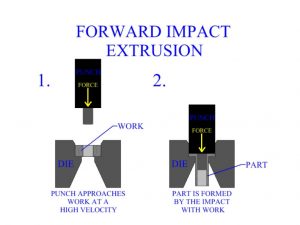

Unlike conventional extrusion, which operates at high temperatures to soften the metal, impact extrusion uses cold metal billets that are extruded under rapidly applied high pressure. With a single stroke, a metal slug can be forced into virtually any shape required. The process works with a wide range of components to deliver a cost efficient, high-quality result.

Because impacting is a single-stroke process, it can output quickly, cutting down lead time for production. The process is repeatable at high speed with a precision part being produced to exacting quality standards.

Although the extrusion process itself is fairly simple, the design and fabrication of the tooling is a highly skilled art. Our experience in this area is passed on to the customer in the form of tight tolerances, high strength, and industry leading parts fabrication.

For more details, please refer to http://thelibraryofmanufacturing.com/impact_extrusion.html

source: thelibraryofmanufacturing.com